During the installation of the Third Red Rock Deli Line nationally we were involved in all works from preparation to completion, commissioning and production.

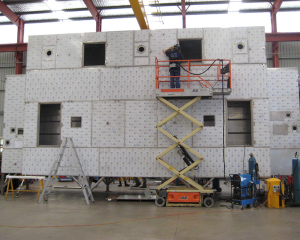

This installation involved the reclaiming of yard space for the extension of the existing building.

An area approximately 50m x 120m was reclaimed, we relocated operational equipment including, storage silos, water heaters and chillers, Waste handling hoppers and silos, Pest control gas system and controls as well as all wall mounted services.

As this affected the entire site operations the relocation works were delicately managed alongside the site operations team to ensure any disruption to production was minimised.

Upon completion of the relocation works, Badge Construction commenced with their part of the extension for which we remained heavily involved, coordinating site and contractor movements as well as facilitating requirements ensuring the maintenance of a safe workplace for all parties involved at all times. Acting on behalf of the client we effectively worked with Badge Construction to ensure timely completion of the building to the required standard.

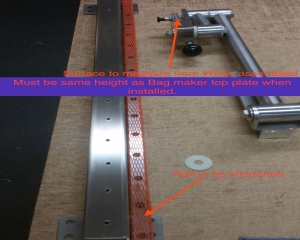

During this time we remained heavily involved in the equipment planning and installation scheduling working with the client and vendors to achieve a mutually beneficial result within time and budget.

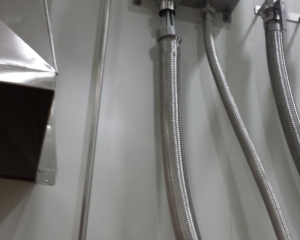

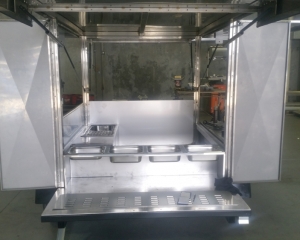

Preparing to full potential all possible services connections, service loops, organising then facilitating mechanical services installation.

On building completion the major vendors completed their individual installations whilst we facilitating the interconnecting systems, services, controls.

The Entire project had a life span of over two years from concept to completion and is deemed a success at a cost of over $36mil, we are proud to have been involved.

Due to legal requirements and confidentiality photo’s posted are limited, please contact us for more information.