As Site Representative for Smiths Snackfoods Sydney based National Project team we oversaw the preparation and completion of a building extension which was undertaken whilst the site was operational. The shutdowns required for services connections, with careful planning, kept downtime to a minimum.

We liaised with the onsite operations and scheduled appropriate times for the fire system connections, electrical tie ins, major transport deliveries and managed the application of epoxy floor coat and painting with the shortest possible production interruption.

When the building extension was complete and the partitioned off area approved by the Site Quality team, we received the carton erector delivery from France, the tray erection, box loading and lidder sections from Germany and the packet feed systems from the USA. These were all then installed in the new extension and commissioned.

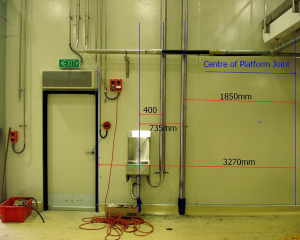

As an extended part of the SEMP project installation several systems were upgraded or extended, shown first is the area where a packaging bay has now been installed and is fully operational. Additional areas of this were; the installation of a new box filling station, installation and commissioning of a bag inner transfer system to carry product from one end of the factory to another and preworks relocations.